Business Consulting

Hydrogen purification technology by pressure swing adsorption and membrane separation

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

Hydrogen purification technology by pressure swing adsorption and membrane separation

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

Hydrogen is an important green and clean energy and chemical raw material, which has been widely used in many fields. Industrial hydrogen production process methods mainly include hydrocarbon steam reforming, heavy oil or coal gasification, methanol steam reforming and ammonia decomposition.etc. The hydrogen obtained by these methods is not high purity and needs further purification. In addition, other mixed gases of hydrogen-containing need to be recovered and purified such as refinery catalytic cracking dry gas, refinery reforming tail gas, synthetic ammonia purge gas, methanol tail gas, crude hydrogen from membrane separation etc.To do this, in response to Meet technology and market demand of purify hydrogen, after years of research and development and industrial application practice, the company now has pressure swing adsorption and membrane separation to purify hydrogen technology, which can achieve high efficiency, high yield, low energy consumption and low cost to obtain high-purity hydrogen products from the hydrogen-containing mixed gas .

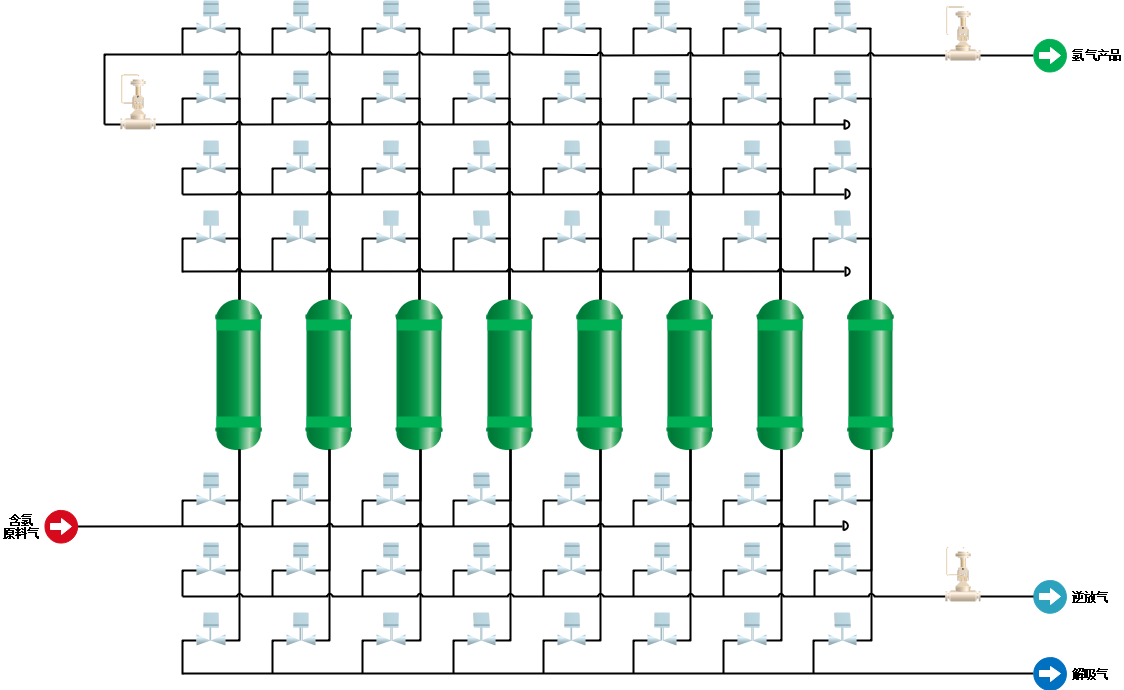

(1) Hydrogen is purified technology of pressure swing adsorption (PSA)

Technical features and advantages

µ Adopting independent research and development, production of a variety of special appropriative adsorbent, compared with the conventional adsorbent performance increased by more than 30%

µ Adopting self-developed patented pressure swing adsorption process technology, the device is flexible , safe and stable in operation, and occupies a small area

µ High hydrogen yield, low energy consumption and low operating cost for hydrogen purification

µ Hydrogen purification is a ripe technology of abundant engineering achievements and rich experience in engineering design and operation

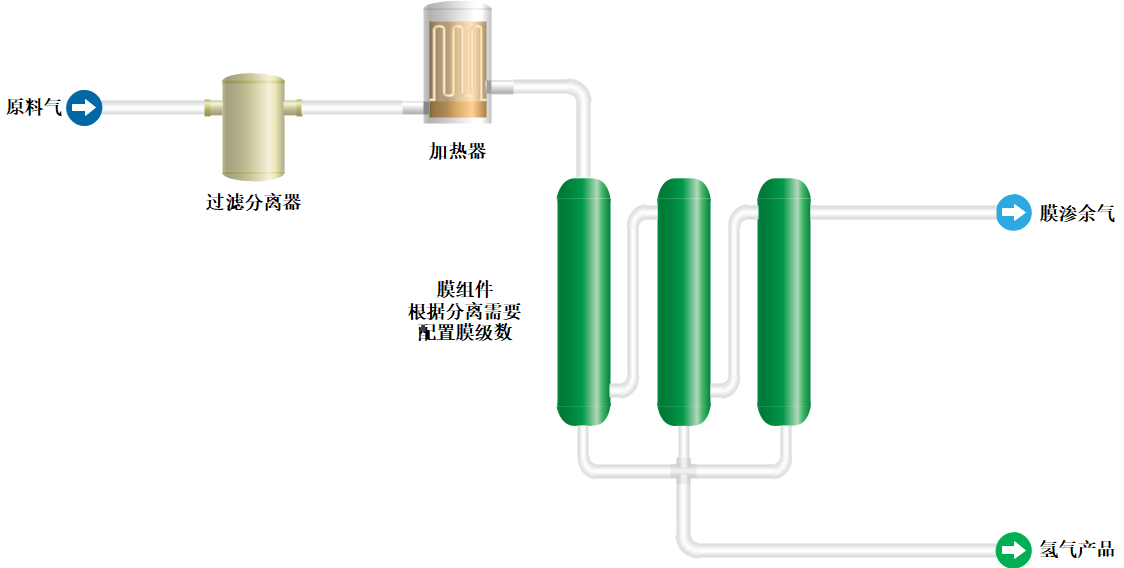

(2) Membrane separation and purification of hydrogen technology

Technical features and advantages

µ Adopting high-performance hydrogen special separation membrane, the core component membrane core has a long service life, an average of more than ten years, the membrane core has excellent physical and chemical properties, and has special anti-pollution attenuation ability

µ Adopting patented design system, high separation efficiency, to achieve high hydrogen recovery rate and purity

µ The whole device has no wearing parts and is easy to operate. Most of them are skid-mounted structures.

Application field

T Synthesis gas, semi-water gas, city gas, coke oven gas, waste gas (blue carbon tail gas), purified gas, fermentation gas, methanol tail gas, formaldehyde tail gas, catalytic cracking dry gas in refinery, reforming tail gas in refinery, synthetic ammonia release Purification of hydrogen in gas, etc.

T Purification of hydrogen in other hydrogen-containing gas mixtures

Scan the QR code to read on your phone

New

Sichuan DKT Energy Technology Co., Ltd.

( A subsidiary of Hydrexia (China))

A subsidiary of Hydrexia (China))

TEL:028-85256712 / 85248678

Switchboard:028-85249678

Company email: dkt@hydrexia.com

Procurement Department: dkt-caigou@hydrexia.com

Website:en.scdkt.com

ADD:Building 3, Area A, No. 1, Chengfei Avenue, Qingyang District, Chengdu City, Sichuan Province

Mobile website

Copyright © 2021 Sichuan DKT Energy Technology Co., Ltd.(A subsidiary of Hydrexia (China)) all rights reserved 蜀ICP备09032657号 Powered by www.300.cn