Business Consulting

Integrated technologies of gas separation and purification in large-scale modern coal chemical industry

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

Integrated technologies of gas separation and purification in large-scale modern coal chemical industry

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

In view of the characteristics and application requirements of the gas composition produced by the clean and qualitative utilization process of modern coal chemical industry, a complete integrated gas separation and purification technology has been successfully developed (including pretreatment, temperature swing adsorption, TSA decontamination, sulfur-tolerant wide-temperature shift, organic sulfur hydrolysis, water elution ammonia, MDEA desulfurization/decarbonization, fine desulfurization/dechlorination, catalytic deoxygenation, acid gas desulfurization and sulfur recovery, PSA extraction hydrogen, PSA concentration methane, PSA concentration CO, membrane separation, etc.) It has been successfully applied in many large-coal chemical projects in China and has been well received by users.

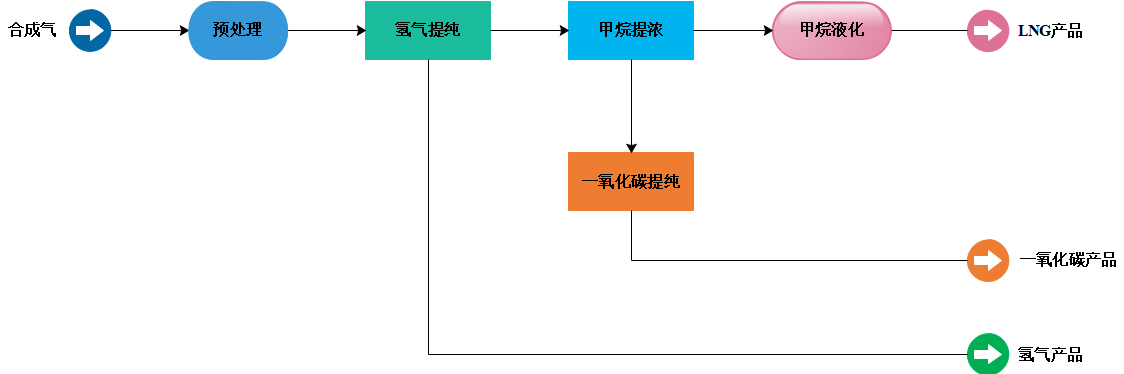

Typical process flow of synthesis gas produces ethylene glycol (by-product LNG)

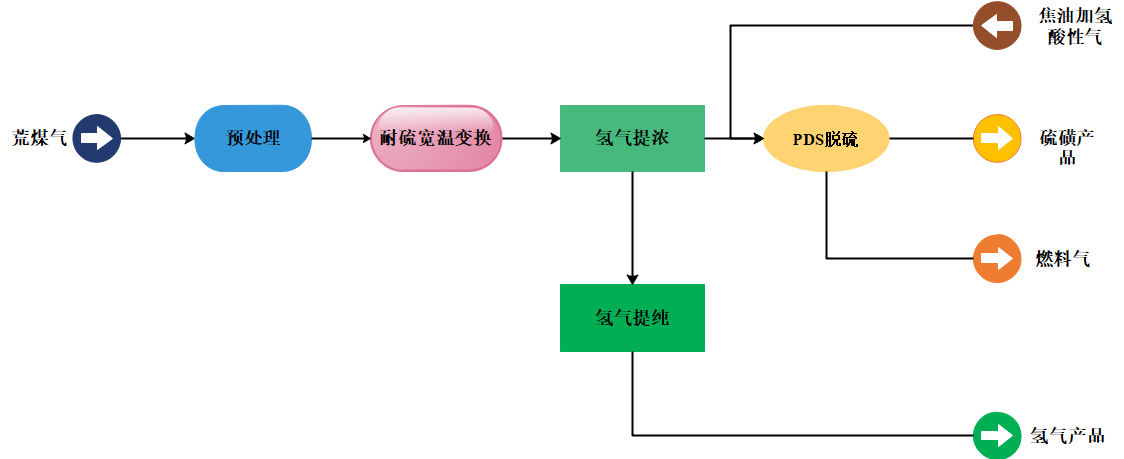

Typical process flow of raw gas produces hydrogen production + desulfurization

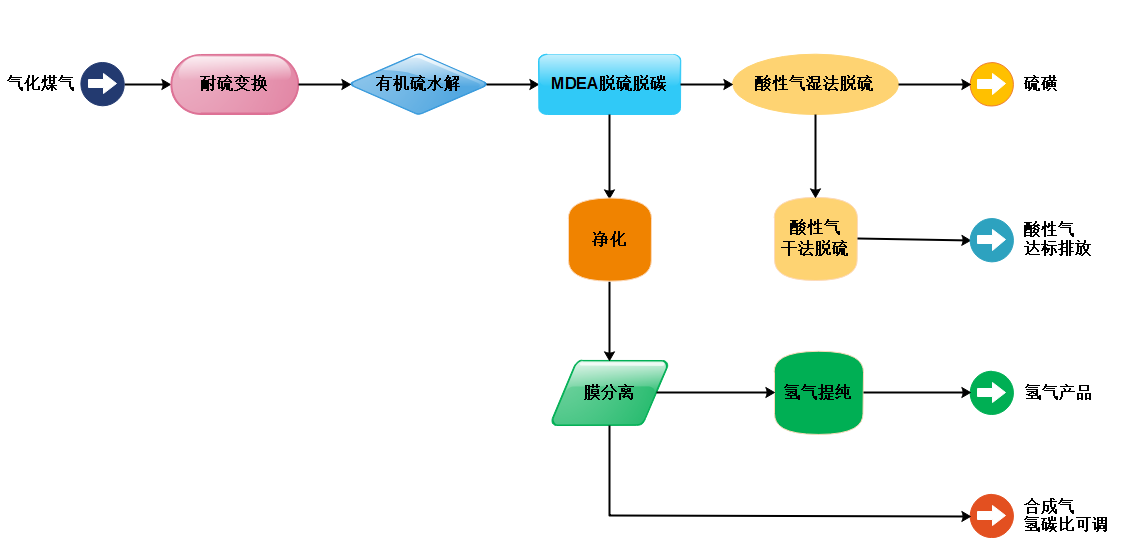

Typical process flow of gasification gas produces hydrogen + synthesis gas (adjustable hydrogen to carbon ratio) + desulfurization

Technical features and advantages

µThe technology is advanced and mature and at the same time safe and reliable operation

µ According to the user's working conditions, there is flexible configuration of integrated technology and besides optimal investment and energy consumption

µ The impurities are highly purified of gas,and subsequently target products are highly purity and yield

µ The devices are highly degree of integration and automation

µ Separation and purification of the comprehensive energy consumption is reduced, and the economic benefit is elevated

Application field

Separation and purification of dry distillation (coke oven gas, semi-coke gas, waste gas, etc.), gasification gas (such as water gas, semi-water gas, synthesis gas, etc.)

Scan the QR code to read on your phone

New

Sichuan DKT Energy Technology Co., Ltd.

( A subsidiary of Hydrexia (China))

A subsidiary of Hydrexia (China))

TEL:028-85256712 / 85248678

Switchboard:028-85249678

Company email: dkt@hydrexia.com

Procurement Department: dkt-caigou@hydrexia.com

Website:en.scdkt.com

ADD:Building 3, Area A, No. 1, Chengfei Avenue, Qingyang District, Chengdu City, Sichuan Province

Mobile website

Copyright © 2021 Sichuan DKT Energy Technology Co., Ltd.(A subsidiary of Hydrexia (China)) all rights reserved 蜀ICP备09032657号 Powered by www.300.cn