Business Consulting

Carbon monoxide purification by PSA technology

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

Carbon monoxide purification by PSA technology

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

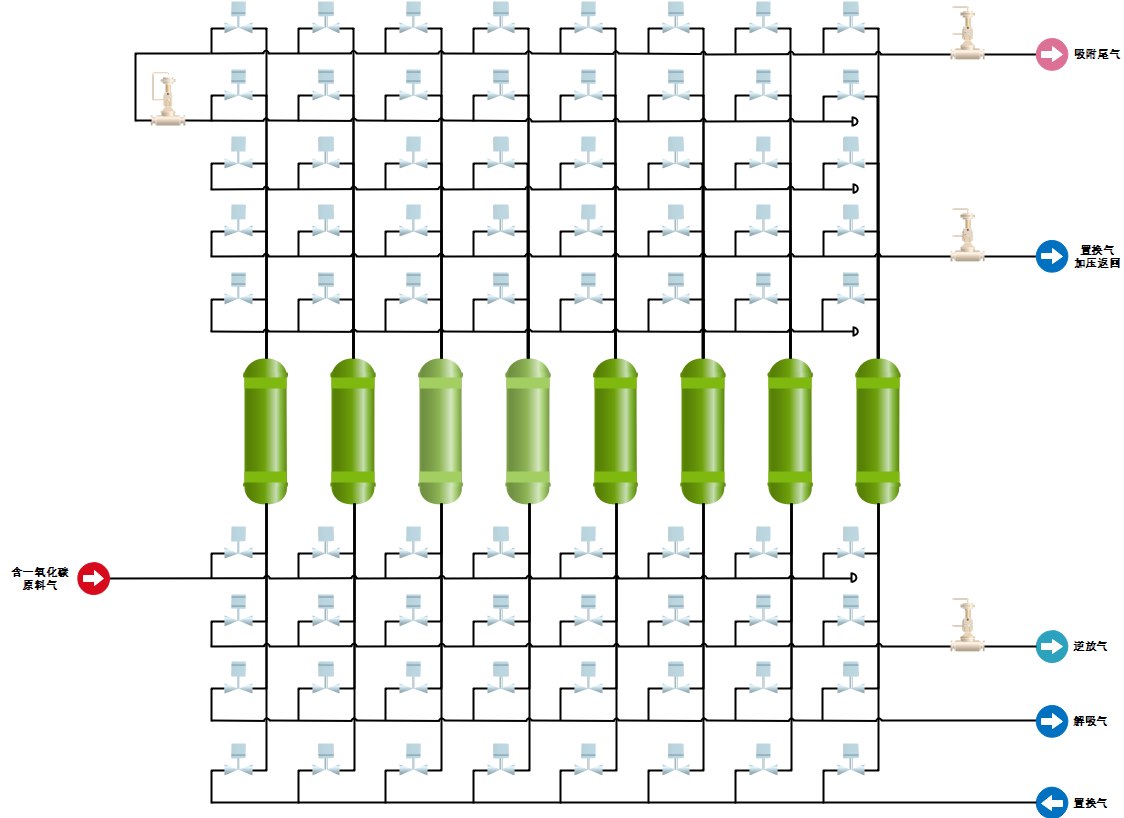

Carbon monoxide is commonly used as conversion hydrogen production raw material, chemical synthesis raw material and reducing agent, etc. The main sources are semi-water gas, water gas, synthetic ammonia copper washing and regeneration, blast furnace gas, converter gas, calcium carbide furnace gas, carbon black furnace gas, yellow phosphorus tail gas, etc. When carbon monoxide is used as a raw material for chemical synthesis, such as ethylene glycol, it needs to be purified to the concentration required for the synthesis process. Therefore, according to the technical requirements and market demand, the company after years of research and development, industrial application practice, now has two kinds of special adsorbent for purification of carbon monoxide and patent technology, high efficiency, high yield, low energy consumption, low cost, purification to obtain high purity carbon monoxide from carbon monoxide gas mixture containing products.

Technical features and advantages

µ Advanced and mature technology, simple process

µ Adopt the special adsorbent for carbon monoxide developed and produced independently, with high separation coefficient and good purification effect

µ The special carbon monoxide adsorbent is pre-reduced before leaving the factory, and can be directly used for on-site loading, without long period of on-site reduction, and at the same time avoid the problem of large gas consumption and chlorine emission pollution caused by the reduction process

µ Adopt self-developed patented pressure swing adsorption process technology, the device is flexible in operation, safe and stable in operation, and occupies a small area

µ It has high carbon monoxide yield, low energy consumption and low operating cost for carbon monoxide purification

Application field

T Purification of carbon monoxide in semi-water gas, water gas, synthetic ammonia copper washing regeneration gas, blast furnace gas, converter gas, calcium carbide furnace gas, carbon black furnace gas, and yellow phosphorus tail gas

T Purification of carbon monoxide in other carbon monoxide-containing gas mixtures

Scan the QR code to read on your phone

New

Sichuan DKT Energy Technology Co., Ltd.

( A subsidiary of Hydrexia (China))

A subsidiary of Hydrexia (China))

TEL:028-85256712 / 85248678

Switchboard:028-85249678

Company email: dkt@hydrexia.com

Procurement Department: dkt-caigou@hydrexia.com

Website:en.scdkt.com

ADD:Building 3, Area A, No. 1, Chengfei Avenue, Qingyang District, Chengdu City, Sichuan Province

Mobile website

Copyright © 2021 Sichuan DKT Energy Technology Co., Ltd.(A subsidiary of Hydrexia (China)) all rights reserved 蜀ICP备09032657号 Powered by www.300.cn