Business Consulting

Carbon capture and utilization technologies for lime kiln gas, flue gas, fermentation gas, etc.

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

Carbon capture and utilization technologies for lime kiln gas, flue gas, fermentation gas, etc.

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

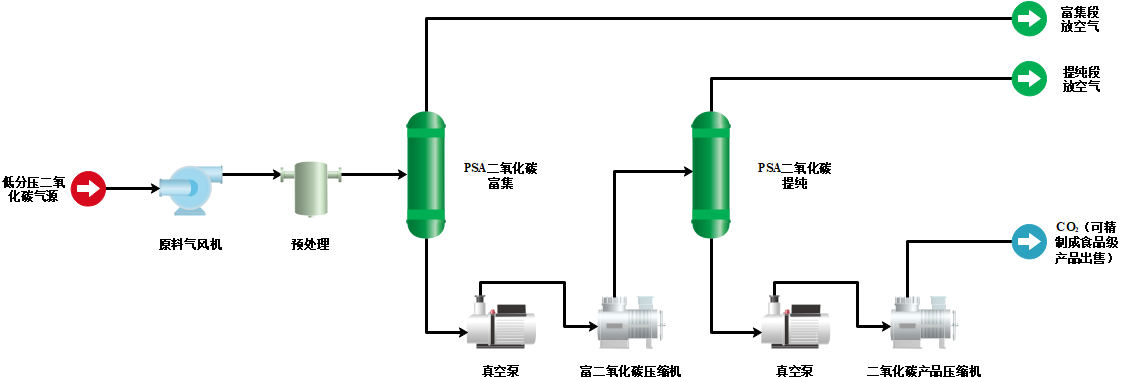

With the steady progress of policies related to the 2030 Carbon peak and 2060 Carbon neutrality targets in China, the demand for Carbon Capture, Utilization and Storage (CCUS) technologies of various Carbon dioxide containing gas sources in the industrial field has significantly increased. Carbon dioxide rich sources such as lime kiln gas, flue gas and fermentation gas are usually at low pressure. Our company has developed two technologies for carbon dioxide separation and recovery. Low partial pressure carbon dioxide pressure swing adsorption (PSA) recovery patented technology, can purify 8~13vol% of carbon dioxide in gas source to more than 95%, carbon dioxide yield of 70~90%. Compound organic amine absorption and separation of carbon dioxide technology, namely MEA as the main solvent, adding active amine, antioxidant and corrosion inhibitor, has high carbon dioxide absorption capacity, low regeneration energy consumption, basically eliminate oxygen degradation side reaction and equipment corrosion is very small. The purity of carbon dioxide gas can reach 99.5% by using this technology. Industrial or food grade carbon dioxide products can be obtained through further purification/liquefaction to achieve carbon capture and utilization.

Technical features and advantages

µ Advanced and mature technology, simple process flow, stable and reliable operation

µ Separation recycling of carbon dioxide purity and high yield of both

µ Low operating energy consumption, low carbon dioxide separation cost, and good economic benefits

µ High degree of automation device, network remote monitoring, unattended

µ Large operating load, strong adaptability to fluctuations in raw gas flow and component content

Application field

T Separation and recovery of carbon dioxide from lime kiln gas, flue gas, fermentation gas, etc. to realize carbon capture and utilization

Scan the QR code to read on your phone

New

Sichuan DKT Energy Technology Co., Ltd.

( A subsidiary of Hydrexia (China))

A subsidiary of Hydrexia (China))

TEL:028-85256712 / 85248678

Switchboard:028-85249678

Company email: dkt@hydrexia.com

Procurement Department: dkt-caigou@hydrexia.com

Website:en.scdkt.com

ADD:Building 3, Area A, No. 1, Chengfei Avenue, Qingyang District, Chengdu City, Sichuan Province

Mobile website

Copyright © 2021 Sichuan DKT Energy Technology Co., Ltd.(A subsidiary of Hydrexia (China)) all rights reserved 蜀ICP备09032657号 Powered by www.300.cn