Business Consulting

CO₂ separation and recycling technology in CCS-EOR process

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

CO₂ separation and recycling technology in CCS-EOR process

- Categories:Technology Introduction

- Author:

- Origin:

- Time of issue:2021-12-21

- Views:0

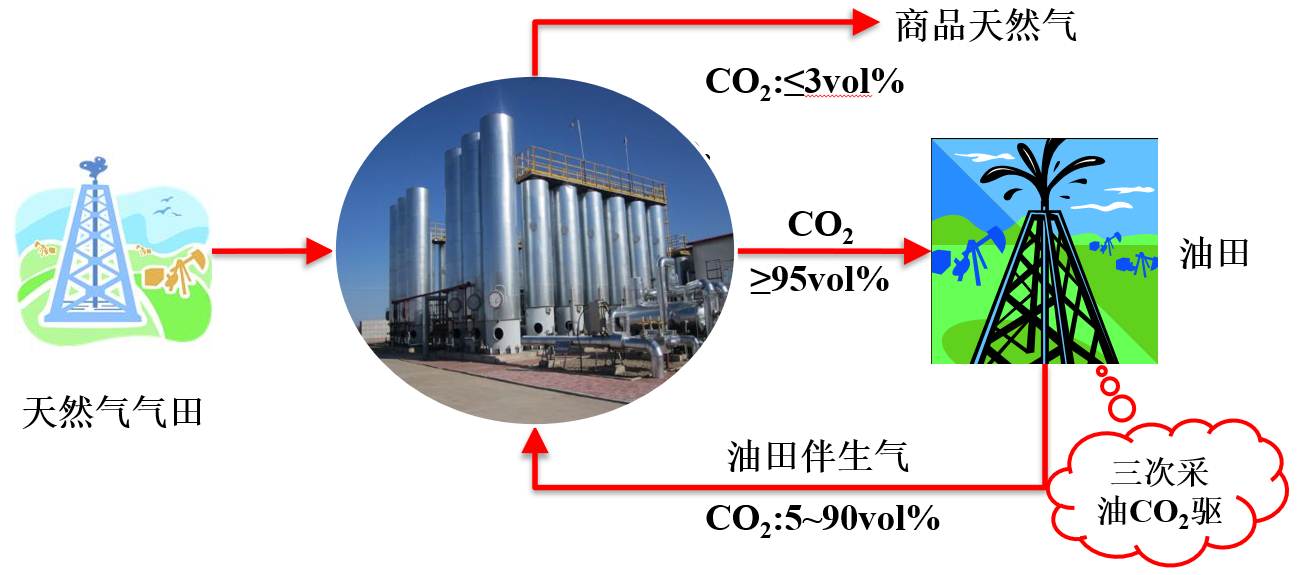

DKT has been committed to the research and development, engineering design and application of related technologies in the field of carbon neutralization, and has developed corresponding recovery methods for carbon dioxide and methane in various industrial gas sources (the greenhouse effect is 25 times that of carbon dioxide). CO2 miscible injection (CO2-EOR) technology is often used at home and abroad to enhance oil recovery, namely CCS-EOR,which is the most widely used and most successful method of CCUS technology abroad, but the resulting oilfield associated gas contains the concentration of CO₂ (5%~90%) fluctuates greatly, and this technology requires a large amount of CO₂ gas source. In response to this technical demand, the company has developed special adsorbents for decarbonization with high CO₂ adsorption capacity and CO₂/hydrocarbon separation coefficient, as well as supporting advanced pressure swing adsorption technology.

At present, the technology has been successfully applied to the CO₂ flooding and storage projects of two oilfield companies of PetroChina, realizing the large-scale demonstration application of CCUS technology in the domestic industry. In 2021, the project was featured by CCTV-13 on CCTV channel. Through efficient and low-cost carbon capture, utilization and storage, it has established an important demonstration for the project area to achieve carbon peak and carbon neutrality as soon as possible.

µ The technology is advance and mature,otherwise the processs is imple

µ CO₂ special adsorbent has high adsorption capacity and CO₂/hydrocarbon separation coefficient

µ The technology fully adapt to the large fluctuation of CO₂ concentration in the raw gas (5~90%)

µ CO₂ product gas has high purity and yield, and hydrocarbon yield is also high

µ The device is highly integrated and has a high degree of automation

µ The separation and recovery cost of CO₂ and hydrocarbons is low, and the economic and ecological benefits are high

µ The whole separation process has no secondary pollution, green and environmental protection

Application field

T CCS-EOR process CO₂ separation and recycling

T CO₂ separation from biogas, landfill gas, etc.

Scan the QR code to read on your phone

New

Sichuan DKT Energy Technology Co., Ltd.

( A subsidiary of Hydrexia (China))

A subsidiary of Hydrexia (China))

TEL:028-85256712 / 85248678

Switchboard:028-85249678

Company email: dkt@hydrexia.com

Procurement Department: dkt-caigou@hydrexia.com

Website:en.scdkt.com

ADD:Building 3, Area A, No. 1, Chengfei Avenue, Qingyang District, Chengdu City, Sichuan Province

Mobile website

Copyright © 2021 Sichuan DKT Energy Technology Co., Ltd.(A subsidiary of Hydrexia (China)) all rights reserved 蜀ICP备09032657号 Powered by www.300.cn